Bli kjent med OMRONs 3D Robot Vision System

Automatisk bin-picking har aldri vært enklere

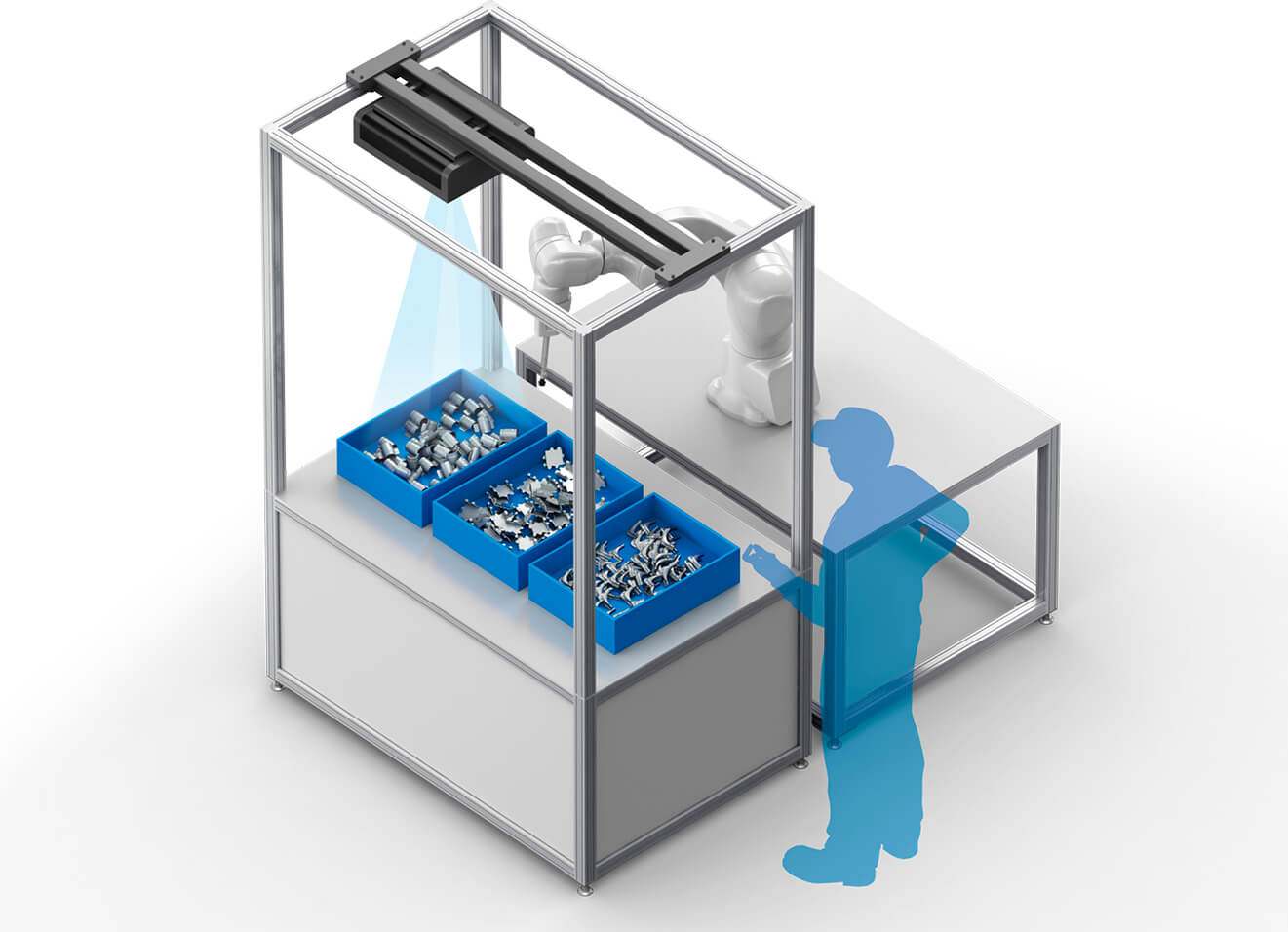

3D Bin picking

Kompakt. Fleksibelt. Enkelt å ta i bruk.

Med OMRONs 3D Robot Vision System får du komplett visionteknologi til effektiv og fleksibel bin-picking med detekteringshastigheter ned til 0,4 sekunder per enhet. Bli introdusert til systemet på gratis webinar.

Et paradigmeskifte for bin-picking

-

OMRON Bin Picking solution for flexible manufacturing

The Bin picking solution from OMRON combines FH-SMD 3D Vision system and the flexible OMRON TM Collaborative robot. The 3D system is used to identify different parts in their individual bin, by combining the 3D system on the hand of the robot the manufacturing cell footprint is drastically reduce compared to traditional fixed vision systems. #omronindustrialautomation #cobots

02:58

Slik fungerer det

- En lettvekts 3D-sensor på 0,6 kg.

- En OMRON robot

- FH 3D Vision System Software

Hvorfor OMRON 3D Robot Vision System?

Med OMRON 3D Robot Vision System er du sikret:

Rask installasjon og igangkjøring: Systemet kommer med innebygde software-assistenter som guider deg gjennom installasjonen. Takket være sin kompakthet er systemet enkelt å ta i bruk i bedriftens eksisterende produksjonslayout.

Høy grad av fleksibilitet: Takket være robotarmens store bevegelsesfrihet kan oppsamling av enheter foregå i mange ulike applikasjoner. Samtidig er systemet enkelt å programmere, og kan på grunn av sin kompakthet, flyttes rundt i produksjonen etter behov.

Komplett løsning: OMRON leverer den komplette løsning i form av robot og visionsystem samt tilhørende Input, Logic, Output og Safety teknologier.

Gratis on-demand webinar

3D robot vision system

Du kan lære mer om OMRONs 3D Robot Vision System på gratis webinar

Arrangert 10. jan, 2023

Få testet din løsning i vårt Proof of Concept - gratis for de 10 første

-

OMRON Proof of Concept

Proof of Concept (PoC) Service helps you to outline and solve your robotics or industrial automation solution. The actual configuration always differs per customer due to different manufacturing flows, materials to be handled, or environment to be operated in. For this reason, it is important and valuable to evaluate the feasibility of application requirements with a PoC Service. Read more about our Proof of Concept on our website:

01:06

Vil du vite mer?

Preferred 3D Robot Vision partners

Amatec

Imperietek

Skala

Omrons 3D Robot vision system

Omron's 3D robot vision system can help users with a manual operation for sorting parts used in the assembly process, which can involve sorting mistakes or injuries due to heavy workload lifting and even difficulty in securing human resources for parts picking. The vision system can also be helpful in scenarios where an overhead mounted camera is not emptying the bins or not fitting the available installation space due to excessive mounting structure size.

Relevant blog posts

Autonomous bin picking with a collaborative mobile robot

16. oktober 2019 Our TM collaborative robot provides a unique solution to easily automate applications such as picking and packing that, traditionally performed by humans, have been challenging to automate. As part of the TM series launch, we also released a mobile-compatible model, which seamlessly integrates into Omron’s LD series autonomous mobile robot. Combined with a 3D vision camera mounted directly onto the collaborative robot, this enables for example e-commerce companies to automate more complex tasks. This includes pick and place of various items onto a tray or container, as well as connecting production processes with the autonomous mobile robots for flexible manufacturing and materials handling.

Unpacking and Distribution of Arriving Goods

Together with our partners OMRON can address unpacking and distribution of arriving goods issues and realize fully automated handling & movement of these goods.

Intralogistics & Intermediate Stocks

Our wide array of smart robotic solutions optimizes the throughput and availability of goods needed.

Lineside Replenishment

We offer a wide array of robotic solutions, not only improving throughput, but freeing workers to concentrate on value-add tasks.

Inspection of incoming goods

Examining incoming materials and products on compliance with specifications. Identifying any problems or defects on criteria as labelling, container size, container integrity or simply quantity.

Persons-to-Goods

Improve productivity and increase accuracy for the warehouse operator pickers that travel around the warehouse, going to the products one by one in the goods gathering process.

Mixed Boxes in Secondary Packaging

To handle & optimize the inflow of different goods, we bring together a complete line of robotic automation products into a single, fully integrated packaging system.

End-of-Line Palletizing

Together with our partners we realize smart and efficient EOL-palletizing solutions.