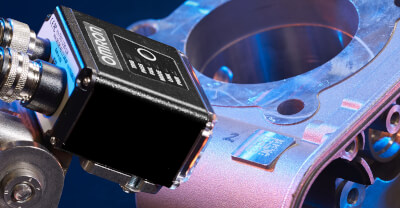

Dra nytte av kvaliteten og påliteligheten til våre løsninger for dine mest krevende produksjonsmiljøer. Omrons innovative og skalerbare løsninger omfatter inndata, utdata, logikk, kontroll, sikkerhet, bevegelse, robotikk og mer. Løsninger med kunstig intelligens møter kundenes behov for pålitelig produktkvalitet og forutsigende vedlikehold.

Enten du ønsker å optimalisere prosessene for montering, drivverk, stempling eller forming, batteri eller en annen viktig kjøretøykomponent, fra inspeksjon og sporbarhet til intralogistikk og montering, har Omron ekspertisen og den komplette teknologiporteføljen for å maksimere produktiviteten.

Find Out what Our Customers Say

Agile and clever tailor-made mobile robotics

4. november 2019 Revolutionize human-machine collaboration in the automotive industry

FasThink optimizes Garnet's intralogistics with mobile robots

2. november 2021 Garnet relies on FasThink to innovate its logistics and production processes.

Mobile robots smarten up Toyota’s new parts centre

28. april 2020 Intelligent robots and sophisticated design are helping Toyota to achieve a higher level of efficiency at its new warehouse in Sydney, Australia.

Related articles

Powering the European automotive industry

29. januar 2021 The European automotive industry is facing strong competition from Asia, as well as the economic challenges of the pandemic. It needs to develop innovative, future-proof strategies and technologies that will boost both efficiency and sustainability. Tony Seba from Stanford University believes that by 2025, no more new vehicles with (pure) combustion engines will be sold and there will be a move towards battery or hydrogen-powered fuel cells. Meanwhile, the industry faces falling sales, increasingly strict emissions regulations, new technologies, digitisation and changing consumer needs. Companies must respond by converting their production lines; becoming more agile; and introducing innovations that provide a competitive edge.

Energizing European battery cell production

1. mai 2020 What can European automotive companies do to future-proof their production lines, especially in relation to battery manufacturing? Robotics, automated quality control and artificial intelligence (AI) can help companies to tackle the strong competition they are facing from Asia.

Green is key: sustainability in battery manufacturing for E-mobility

5. februar 2020 How can automation solutions with artificial intelligence help optimize maintenance and production for sustainable manufacturing?

Product Solutions

Our Partners

Through the OMRON Innovation Network, we are bridging the gap between our technology and fully integrated systems and solutions. By closely collaborating with strategic partners, we tap into their collective knowledge, expertise, and shared drive to provide a clear pathway for customers to realise solutions to their manufacturing challenges.