Today’s Challenge: A Reliable Traceability System

Our Solution: Reliable in- and offline verification to prove compliance

We provide a wide range of code verification solutions that measure code quality according to the relevant ISO and GS1 standards and that help manufacturers to control print quality.

To prove compliance, code verification is done on a sample basis using offline measuring devices such as the Omron LVS verifiers that generate full verification reports as proof of compliance. With the built-in verification algorithm in our vision systems and code readers, we also provide process control solutions to check the print quality of each code produced. We guarantee your code quality.

Benefits of our code quality verification solutions:

-

Documented compliance with traceability directives

-

Guaranteed readability of traceability codes

-

Reduced downtime and rework caused by unreadable codes

-

Avoided penalties or returns associated with unreadable codes

See Our Solution in Action

-

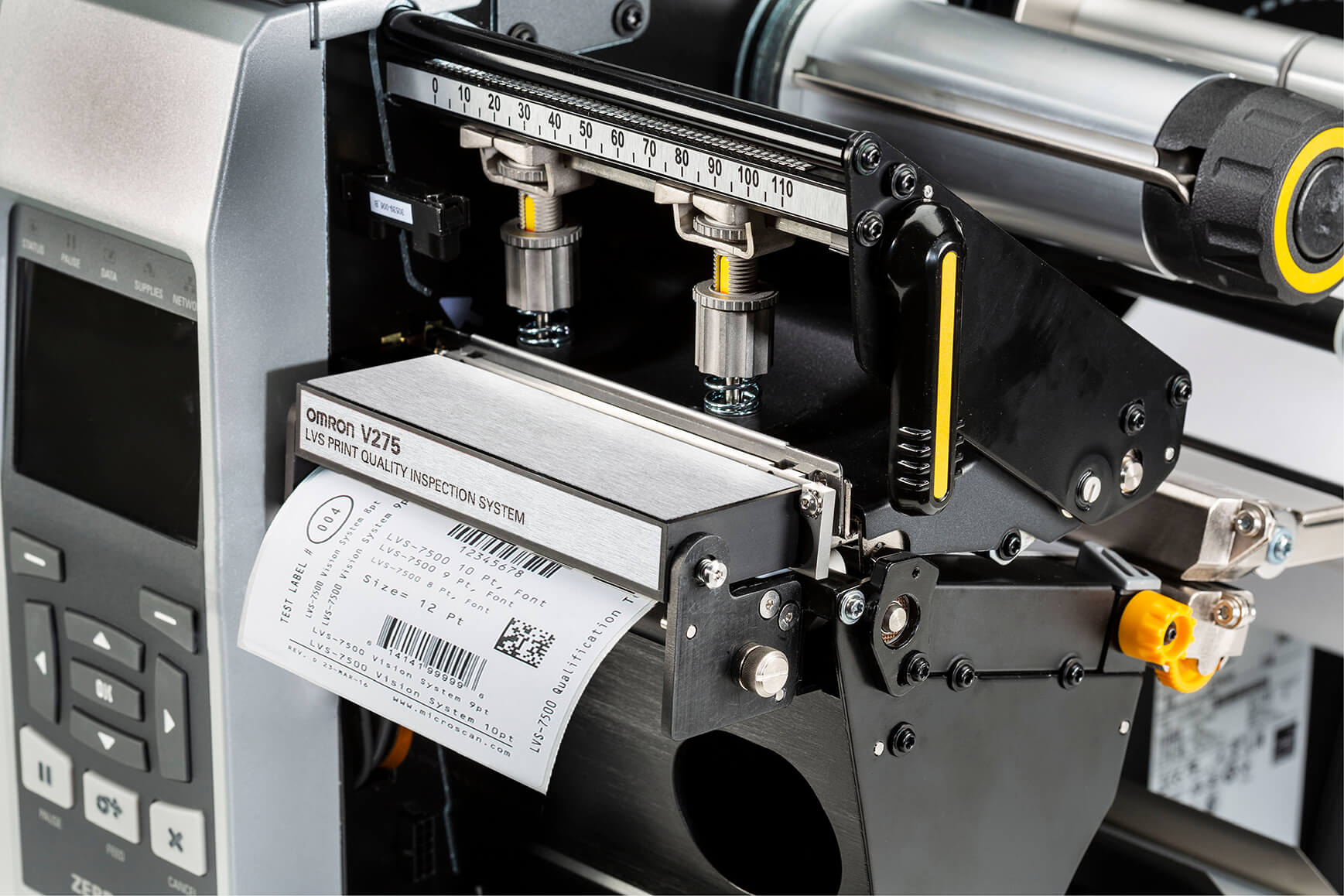

7 Steps to Ensure Label Print Quality with OMRON V275

Introducing the new V275 Series label inspection solution The V275 Series is the ideal label inspection solution for manufacturers using Zebra thermal printers. It makes sure the product and packaging labels show the correct content, are clearly legible and meet mandated quality requirements. 7 Steps to Ensure Label Print Quality with OMRON V275 1. Label designer created a label in the design software and make sure all required content is included 2. Label design is checked for barcode grading and data structure using the OMRON V275 off-line verifier 3. Label design is imported into the V275 via scanning of the representative labels. 4. Label inspection criteria are established in the V275 software 5. Label inspection template is pushed into production 6. Production runs batch of labels and determines inspection results 7. Based on the label production results, adjustments are made to the label design, printing system, or inspection criteria Learn more about the V275:

03:23

7 Steps to Ensure Label Print Quality with OMRON V275

Introducing the new V275 Series label inspection solution The V275 Series is the ideal label inspection solution for manufacturers using Zebra thermal printers. It makes sure the product and packaging labels show the correct content, are clearly legible and meet mandated quality requirements. 7 Steps to Ensure Label Print Quality with OMRON V275 1. Label designer created a label in the design software and make sure all required content is included 2. Label design is checked for barcode grading and data structure using the OMRON V275 off-line verifier 3. Label design is imported into the V275 via scanning of the representative labels. 4. Label inspection criteria are established in the V275 software 5. Label inspection template is pushed into production 6. Production runs batch of labels and determines inspection results 7. Based on the label production results, adjustments are made to the label design, printing system, or inspection criteria Learn more about the V275:Related Products

See also our other Key Applications & Solutions

Laser Marking

Laser marking provides the most durable marks and easy to read codes to guarantee that parts can be identified throughout the life cycle of the product.

Code Readers & RFID

A major obstacle for effective logistics management is the problem of inconsistent identification and therefore limited traceability. Our wide portfolio of code reading & RFID products help you solve your traceability challenges.

Communication & Implementation

Traceability is all about reliable data collection at all stages of manufacturing, without impacting production efficiency. The challenge is to realize reliable data collection with limited implementation costs.