The transition to Pharma 4.0 requires the highest availability and reliability of data to optimise processes, achieve the highest quality and productivity, and ultimately increase OEE. From extracting data while maintaining its integrity to ensuring transparent connectivity with higher-level control and management systems, our automation technologies provide a seamless and reliable solutions for the most demanding data management requiements in the pharmaceutical industry.

Challenge

Extracting the right data, processing it, and converting it into valuable information is key to the digital transformation journey in the pharmaceutical industry. Therefore, it is a top priority for manufacturers and operators to ensure that data extracted from the line is securely registered, saved, stored, and transmitted where needed, so they can act accordingly to keep operations running smoothly, even in the case of power failures or unexpected events.

Solution

OMRON provides a wide range of solutions at the machine level to support the journey to Pharma 4.0. From 'Zero Data Loss', our promise to run a compliant SCADA on the IPC with an intelligent PSU/UPS (Power Supply Unit/Uninterruptible Power Supply) buffer and connected to your head PLC, to our camera-based 'Factory Drive Recorder' system to make surveillance and playback of the process easy and seamless, all embedded with transparent and secure connectivity to databases and cloud base systems.

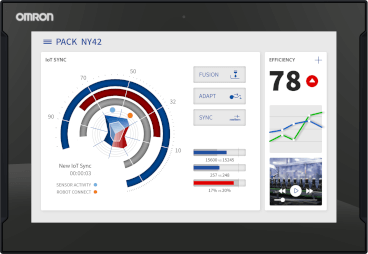

Zenon user interface hosted by an OMRON IPC solution

'Zero Data Loss' emphasizes that GMP-relevant information must be retained under all circumstances during operation, especially during power failures. The essential foundation for this is a high-quality IPC with FDA-compliant HMI, which prevents issues during operation. In the event of a power failure, the programmable Uninterruptible Power Supply (UPS) manages a coordinated shutdown of all participants, providing a stable and adjustable voltage level regardless of the battery's charging state. All necessary status and preventive maintenance information is available, ensuring that the SCADA system can continue to operate smoothly.

Enabling Technologies

Industrial Monitor

Display and touch interface for the Industrial PC Platform.

Information, Control and Safety

The NX5 modular controller integrates control, information and safety, providing a new level of speed to manufacturing sites. Speed up all processes from commissioning to operation and maintenance.