What to consider when selecting a mobile robot for heavy loads

Publisert 11. september 2020 i Flexible Manufacturing

Benefits of mobile robots in the factory of the future

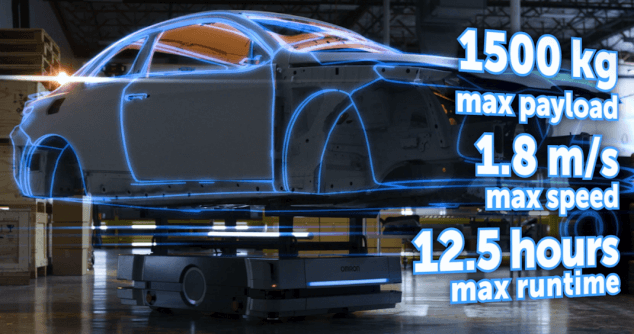

AMRs play a major role in innovating supply chains by optimizing the traceability, speed and accuracy of routine operations. In warehousing and manufacturing they make processes more efficient working safely side-by-side with humans, and reducing the risk of employee injury in dangerous situations. To meet the needs of flexible production, manufacturing sites must be agile enough to change or update a production line at short notice. Since mobile robots aren’t fixed, they support this call for flexibility. Furthermore, innovative robots such as OMRON’s HD-1500 can transport loads up to 1,500 kilogram, expanding application options to pallet-size loads and large and heavy automotive components for example.

When selecting a mobile robot for moving heavy loads, there are five key areas to consider:

1. What are the payload requirements?

When selecting the right mobile robot model for their operations, decision makers obviously need to look at the loads that need to be moved. Mobile robots with lower payload capacity are normally less expensive and more agile than models for heavier loads. The HD-1500 can move pallet size payloads in manufacturing facilities, becoming a viable alternative to forklifts. Since it is built with sturdy metal skins, it is robust and able to withstand heavy unintended external impacts. Onboard sensors are protected as the robot completes demanding tasks.

2. How easy is the solution to deploy?

Mobile robots are easy to implement and provide flexibility because they can move more freely, without predefined routes, and can also be easily reprogrammed according to the task and calculating their own trajectory in real time, working safely side-by-side with people. They enable easy collaboration between humans and mobile robots, but also between various types of mobile robots, and between mobile robots and other machines. A good fleet management system will help to maximize investment, as it helps to minimize the number of robots needed by coordinating them so that they share the tasks.

Modern mobile robots can automatically calculate the best route for material transportation while navigating safely around people and obstacles without the use of magnetic floor tapes or other guides. A typical example is a robot designed to deliver packages to a fixed location whilst automatically avoiding people or obstacles in its path. The robot can identify its own position by comparing the results from a laser scanner with an onboard map.

3. What is the impact on safety?

According to a recent study, one of the most frequent accident risks in European companies is the lifting and moving of heavy loads or persons (54 percent of respondents from 28 countries stated this). Innovative mobile robots can take over these tasks while also improving safety since they come with extensive features, that avoid collisions and obstacles, also when the mobile robot is rotating. When an obstacle is detected, the mobile robot can react dynamically by slowing down, instead of abruptly stopping. The most advanced mobile robots are also capable of moving at high speed in aisles as narrow as three metres. Other useful features are 360° safety coverage and stop position accuracy supporting a collaborative and safe working space. Safely automating material transport operation is an area rapidly being enhanced with mobile robots in industries worldwide as a method not just to meet labour shortage challenges but to manage the risks associated with the spread of the Coronavirus.

4. Battery price vs performance?

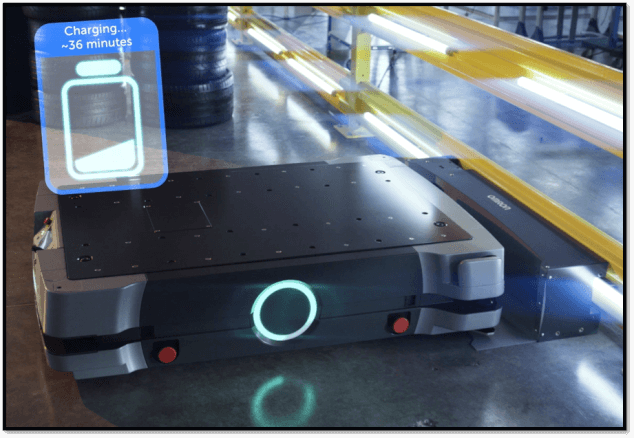

Onsite logistics, the movement of products and material within the factory and warehouse, is becoming a bottleneck for many companies due to the frequency and tediousness of the job, compounded by rising labour costs and the need to meet social distancing protocols. Fast-paced manufacturing environments require speed and flexibility. When selecting the right mobile robot for a specific application, other important aspects to consider in this respect are battery price versus performance. Companies decide if they would rather invest in a low performance battery that will need to be replaced within a couple of years or a more powerful battery with up to 11 hours uptime and 9,000 charge cycles, ensuring 10 years of operation 24 hours a day with a charge time of just 36 minutes.

5. How flexible is the solution and what kind of add-ons are available?

Manufacturers such as OMRON are increasingly focusing on the ability of robots and machines to interact seamlessly. This enables production runs to be quickly and easily altered to allow for fluctuating lot sizes, and also reduces the need for workers to carry out repetitive tasks and heavy lifting. Autonomous robots can be programmed with artificial intelligence (AI) to recognize and learn from their surroundings and make decisions independently. A practical example for the use of mobile robots in food and beverage manufacturing is trashcan handling in the area of recycling supported by system integrators: with specialist add-ons mobile robots can for example pick up and empty trash cans.

Conclusion: Mobile robotics become an innovative pillar in modern production

Over the years, the face of manufacturing has changed considerably – and it continues to do so. Now, a new phase is beginning, where machines are working more interactively with people. Companies such as OMRON are looking towards the future of manufacturing by developing solutions that involve greater collaboration between man and machine. Also with the option to be equipped with a collaborative robot arm, in many applications, mobile robots are well-suited for working side-by-side with human colleagues, for example moving loads from conveyor to conveyor, thus increasing flexibility and efficiency in the production environment.

A new generation of mobile robots will help to ensure the future of manufacturing by enabling production sites to be much more agile, with flexible production lines that can adjust rapidly to meet changing consumer needs but also diverse production demands such as lifting and transporting heavy loads. This in turn will enable manufacturers to be more responsive, more productive and ultimately to enjoy greater profitability.