Taking the first steps to successful digitalisation

Publisert 12. november 2024 i Industry 4.0

Why digitalise manufacturing?

Furthermore, product life cycles are shorter than ever. Whilst the average life cycle of a car model used to be five to eight years, today, with the advent of electric vehicles, it is 12 months or even less. Players in this market cannot afford to take a year for set-up and ramp-up of a new line. They need to complete these phases in weeks rather than months to stay ahead of the innovation curve.

By creating a virtual model of a new machine or line, projects can be de-risked and the time it takes to build and test the installation can be dramatically reduced as costly mistakes are made in the virtual rather than the real world. This is beneficial to any manufacturing industry, but in particular the automotive industry, where there is huge pressure to accelerate time to market and minimise the risk of failure for new products.

The advantages of digitalisation don’t end with virtual commissioning. This is just the beginning. The virtual twin mirrors the physical system in real time and can be run over the lifetime of a system or product, so there is always an opportunity to check - in a safe parallel digital environment - how new materials, new ingredients or new tools will behave.

Digitalisation offers a way of mitigating risk, accelerating production ramp-up and building unprecedented flexibility into business models.

How to digitalise manufacturing?

The key to realising a digital factory is connecting the two worlds of IT and OT. For years, this was considered impossible because they are so different - like getting Martians and Venusians to talk to one another.

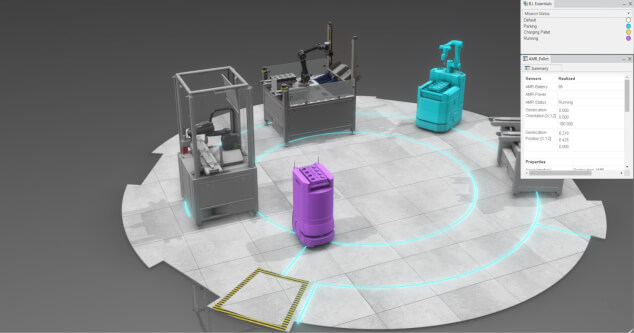

In a digital factory, everything from the sensors to the ordering system needs to be part of a factory-wide network. But it’s not enough for every function to be connected - they need to be able to generate data and share it with one other. And they also need to know how to interpret and action that data. For example, if the ordering system is told that a plastic isn’t available and that a replacement material with a slightly different technical specification will be supplied instead, the ordering function needs to communicate this to the line so that the machine settings can adjusted accordingly. Cyber physical systems are the building blocks of these networks, providing the link between the various components.

Self learning and adaptive systems are another pillar of successful digitalisation. Machine learning algorithms are applied to process large volumes of product, line and machine data. This empowers manufacturers to optimise time-consuming aspects of the manufacturing process, including quality control, equipment maintenance and product design.

The other critical success factor is getting humans and machines to cooperate and work in harmony. By leveraging AI and robotics, manufacturers can benefit from the interactions between humans and machines that can take manufacturing to a new paradigm of flexibility and customisation.

All of this is heavily dependent on intensive and long-term collaborations. Indeed, the only way for the manufacturing industry to harness the potential of digitalisation is for experts from different specialisms to work together. This may entail forming partnerships with customers, suppliers, service providers, companies from other industries, academic institutes, startups, and even competitors. These kinds of collaborations result in complex business ecosystems and synergies that are capable of spawning ground-breaking solutions.

It is an approach that requires openness - most machine builders decline to open up the internal functionality of their machines because they are concerned that will give away the secret of what makes them unique in the market. But the only way of bringing the two worlds of OT and IT together is to create ecosystems that operate on mutual trust.

OMRON’s partner in digital manufacturing design is Dassault Systèmes. If the capabilities of both companies are overlaid onto the ISA-95 functional model - often referenced as a framework for digital factory design - it creates an ideal fit, that is, a complete ISA model filled with the combined competencies.

Digitalisation has an irrefutable role to play in enabling ever-greater flexibility and customisation, shorter innovation cycles and more sustainable manufacturing in a range of manufacturing industries. We’re expecting to see everything from e-vehicles and antibiotics, through to chocolates and lipsticks produced in digital factories in the not so distant future.

Contact us for more information