From manual functional safety checks to guided testing: Modernising safety verification

Publisert 6. mai 2025 i Flexible Manufacturing

From manual funtional safety checks to guided testing: Modernising safety verification

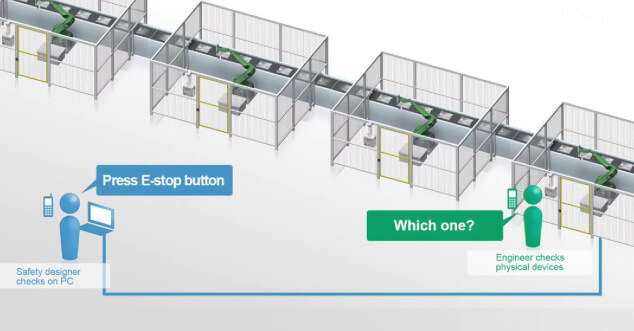

Functional safety is fundamental to every industrial automation system. From emergency stop buttons to interlocks and light curtains, the role of safety components and its safety chain is to protect people and to ensure machine integrity and regulatory compliance. Yet verifying that these systems work correctly, especially during commissioning and maintenance for the entire lifetime of machinery, remains a complex and time-consuming task with high costs in many factories.Traditional safety verification: Manual, repetitive, and labour-intensive

A smarter approach: Online Safety Functional Test Verification in Sysmac Studio

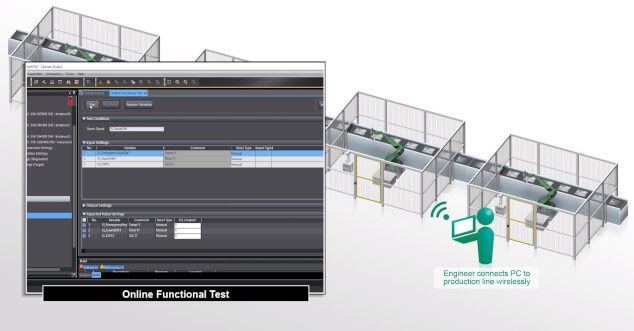

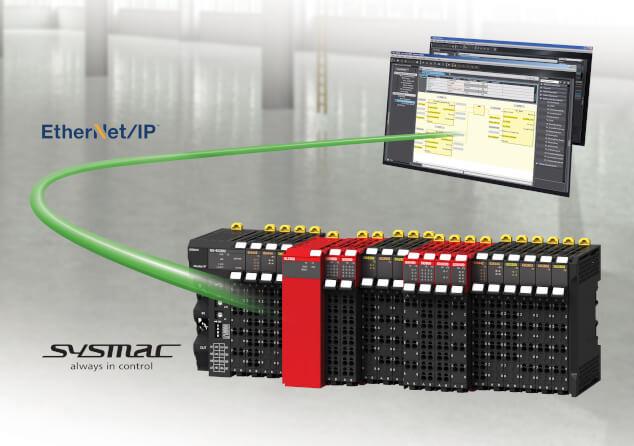

OMRON’s NX Safety platform introduces a more efficient and reliable way to verify safety functions through a feature called Online Safety Functional Test Verification. Integrated into the Sysmac Studio software, this tool enables operators to validate safety (Input-Logic-Output safety chain) logic and device responses directly on live systems—without needing to script tests manually or rely on coordination between multiple persons.

The concept is simple: connect a PC to the NX Safety Controller, either via Ethernet or wirelessly, and open the Online Functional Test tool within Sysmac Studio. The software guides the user through each action and verification step, prompting the operator to activate specific safety components in sequence. As each action is performed—such as pressing an emergency stop or breaking a light curtain beam—the tool captures the corresponding response from the safety program and logs it, complete with timestamps. Results are displayed in real time and can be reviewed on the spot.

Clear reporting and digital traceability

Once all steps are completed, the software generates a test report, including a safety signature. Regularly, this signature also appears on the controller’s seven-segment display, providing a simple visual confirmation that the system has the same verified program. Reports can be exported and archived, creating a reliable audit trail for safety certification or future inspections.

The tool also supports re-testing of failed steps, annotation of observations, and repeat testing after modifications—making it a practical solution for both initial commissioning and ongoing maintenance activities. Because the system records each interaction digitally, it improves traceability and supports compliance with relevant international standards, including IEC 61508 (SIL3) and ISO 13849-1 (PLe).

Fewer resources, greater confidence

One of the major advantages of the Online Safety Functional Test is that it reduces the number of skilled personnel required during verification on site. In many cases, a single operator can complete the entire test cycle, just following the on-screen instructions and interacting with physical components without needing a second or many persons to monitor the system remotely. This not only saves time but also helps standardise procedures across teams, shifts, or sites.

OMRON’s NX Safety platform offers a complete solution for modular, scalable, and standards-compliant safety control. The Online Safety Functional Test Verification feature brings a valuable tool to engineering teams seeking to reduce risk, streamline verification, and improve documentation, whilst maintaining full control over system safety.

Contact us for more informationOnline Safety Functional Test: From manual functional safety checks to guided testing

From manual functional safety checks to guided testing: Modernising safety verification. Online Safety Functional Test reduces the number of skilled personnel required during verification on site.

- 2:13 - From manual functional safety checks to guided testing: Modernising safety verification. Online Safety Functional Test reduces the number of skilled personnel required during verification on site.