E5_D

Next generation of controllers

E5_D is the next generation controllers designed to achieve optimal and automatic temperature control without human intervention. In fact from now on all typical adjustments made in field by expert are now automated using Artificial Intelligence A.I.

- Adaptive control for self optimization of control setting due to process changes

- Specialized function for better sealing application (packaging) and for watercooled extruders (plastic)

- Draw-out structure for easier maintenance operation

- Same basic specification of E5_C series

Specifications & ordering info

| Produkt | Size | Functions | Number of control loops | Temperature input type | Linear analog input type | Temperature range | Features | Number of event inputs | Number of alarm outputs | Supply voltage AC | Supply voltage DC | Control output | Communication port(s) | Terminal type | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Linear current output,, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Voltage pulse output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 100-240 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 2 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 48 mm, Relay output, 2 Alarm outputs, 24 V, Push-in, -200-2300 °C, 2 Event inputs, Serial RS-485 |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX, RS-485, Ht. Burnout SSR fail., 100 to 240 VAC |

|

||

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | HB/HS alarm for 1-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Serial RS-485 | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x 12 VDC pulse OUT, 2 AUX,RS-485, Ht. Burnout SSR fail., 24 VAC/DC |

|

|

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 100-240 V | Relay | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 100 to 240 VAC |

|

|||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Screw | Temp. controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/16 DIN (48 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 2 | 20.4-26.4 V | 20.4-26.4 V | Relay | Push-in | Temperature controller, PRO, 1/16 DIN (48 x 48 mm), 1 x Rel. OUT, 2 AUX, 24 VAC/DC |

|

||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Linear current | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Linear current outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Linear current, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Linear current output, Voltage pulse output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Voltage pulse outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | Relay, Voltage pulse | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, Voltage pulse output, Relay output, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 100-240 V | 2 Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Relay outputs, 4 Alarm outputs, 100-240 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

|

1/8 DIN (96 x 48 mm) | HB/HS alarm for 3-phase heaters, Heater burnout detection, ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | Remote SP, Transfer output | 4 | 4 | 20.4-26.4 V | 20.4-26.4 V | 2 Relay | Serial RS-485 | Push-in | Advanced Digital Temperature Controller, 48 x 96 mm, 2 Relay outputs, 4 Alarm outputs, 24 V, Push-in, -200-2300 °C, 4 Event inputs, Serial RS-485, HB/HS alarm for 3-phase heaters, Transfer output, Remote SP |

|

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 100-240 V | Voltage pulse | Screw | Temp. controller, PRO, 1/8 DIN (96 x 48 mm), 1 x 12 VDC pulse OUT, 4 AUX, 100 to 240 VAC |

|

|||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 20.4-26.4 V | 20.4-26.4 V | Voltage pulse | Screw | Temp. controller, PRO, 1/8 DIN (96 x 48 mm), 1 x 12 VDC pulse OUT, 4 AUX, 24 VAC/DC |

|

||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 100-240 V | Relay | Screw | Temp. controller, PRO, 1/8 DIN (96 x 48 mm), 1 x Rel. OUT, 4 AUX, 100 to 240 VAC |

|

|||

|

|

1/8 DIN (96 x 48 mm) | ON/OFF control, PID control | 1 | B, C (WRe5-26), E, J, JPt100, K, L, N, P (PLII), Pt100, R, S, T, U | 0 to 10 V, 0 to 20 mA, 0 to 5 V, 1 to 5 V, 4 to 20 mA | -200-2300 °C | 0 | 4 | 20.4-26.4 V | 20.4-26.4 V | Relay | Screw | Temp. controller, PRO, 1/8 DIN (96 x 48 mm), 1 x Rel. OUT, 4 AUX, 24 VAC/DC |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Kontakt meg E5_D

Takk for din forespørsel. Vi vil kontakte deg så snart som mulig.

Vi har for tiden tekniske problemer. Ditt skjema har ikke blitt innsendt. Vi beklager så mye og håper du vil prøve igjen senere. Detaljer:

DownloadTilbud for E5_D

Ved å fylle ut dette skjemaet vil du motta et tilbud på det valgte produktet. Vennligst fyll inn alle obligatoriske felter. Dine personlige opplysninger vil bli behandlet konfidensielt.

Takk for din tilbudsforespørsel. Vi vil sende deg det forespurte tilbudet så snart som mulig.

Vi har for tiden tekniske problemer. Ditt skjema har ikke blitt innsendt. Vi beklager så mye og håper du vil prøve igjen senere. Detaljer:

DownloadFeatures

Adaptive control algorithm

-

E5_D Temperature contoller: Adaptive control algorithm

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the E5_D Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

01:26

With standard temperature controllers, not only do you need a long time to define initial start-up PID settings, but it is also really challenging to make the optimal adjustments without having many years of experience in this area. That’s why Omron developed the E5_D Series with “adaptive control technology”. This automatically detects changes in the process under control and adapts the PID accordingly.

Perfect sealing temperature control for packaging machines

-

E5_D TC: Perfect sealing temperature control for packaging machines (1)

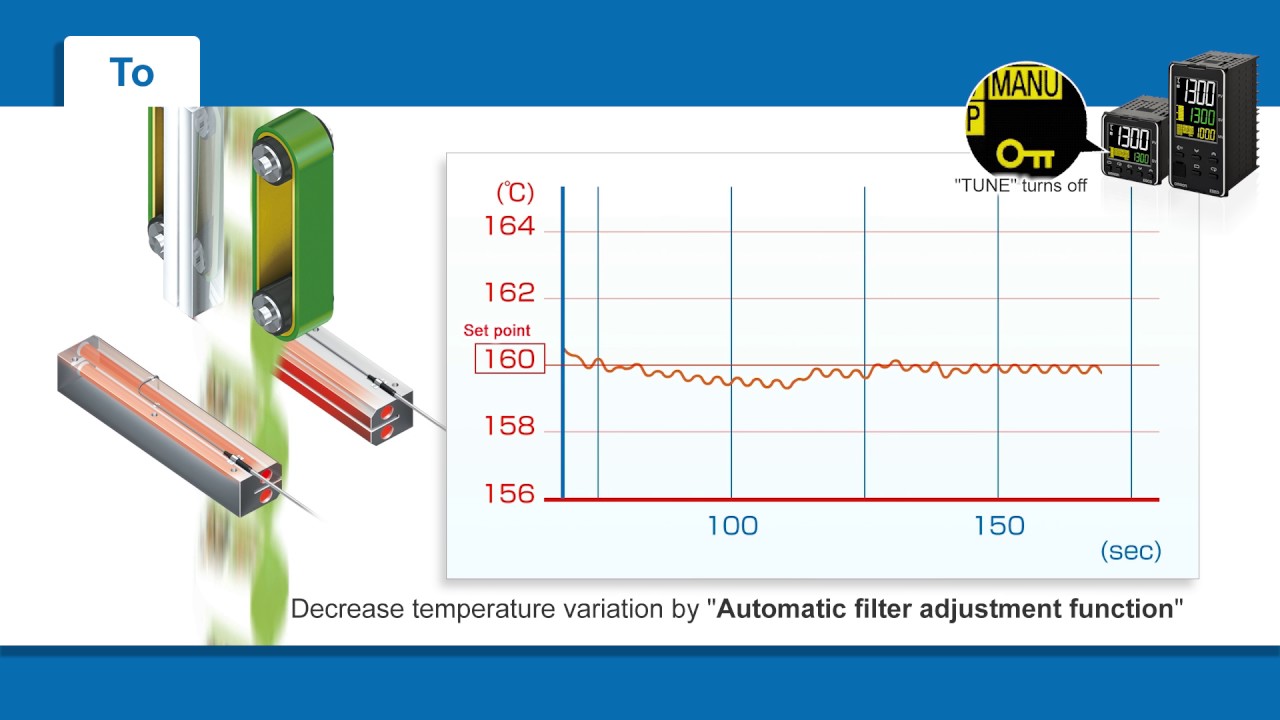

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:25

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature.

Thanks to the E5_D series, this issue is solved with the following approach:

- bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection

-

E5_D: Perfect sealing temperature control for packaging machines (2)

On a conventional sealing machine temperature sensors can often be located too far away from the sealing surface of the heating bar. This causes a difference between the temperature of the sealing surface and the temperature that was actually being controlled. This temperature difference and resulting sealing failures, increase as the packaging speed increases and also in correlation with thinner packaging materials or changing in ambient temperature. Thanks to the E5_D series, this issue is solved with the following approach: • bringing sensor closer to the sealing surface - thanks to special temperature sensor models for faster detection • adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

01:03

- adopting special algorithms (automatic filter adjustment function) built-in E5_D, specifically developed to suppress temperature variations. The result is a better sealing quality of the packages.

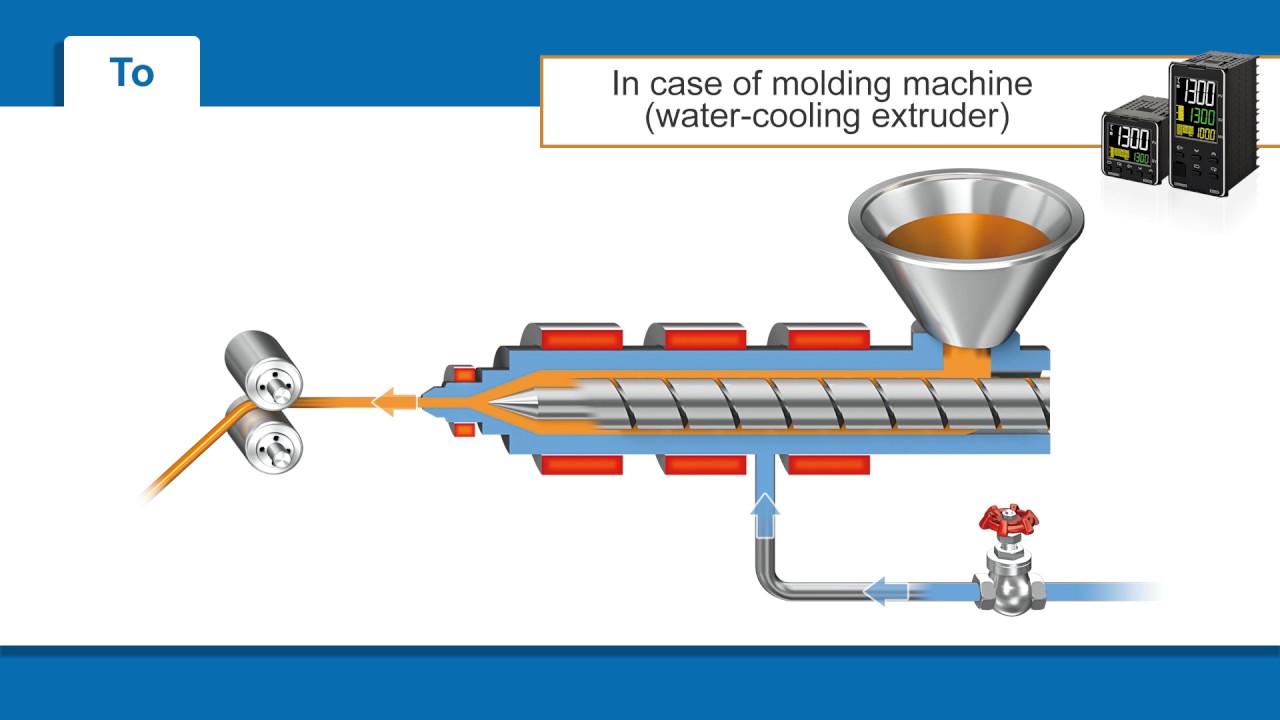

Water cooling output adjustment

-

E5_D TC: Temperature variations in molding machines minimized by a new algorithm

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality… With the E5_D, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

01:33

On a water-cooled extrusion molding machine, increased speed leads to temperature variations due to various factors such as the materials compounding and cooling water…For human operator that means repeatedly make valve adjustments to stabilize the quality. However It is really difficult to achieve high speed production while also maintaining the quality…

With the E5_D, the water-cooling output adjustment function suppresses the temperature variations to a minimum and raises the production capacity with the quality maintained

Downloads

_cg_en.jpg)